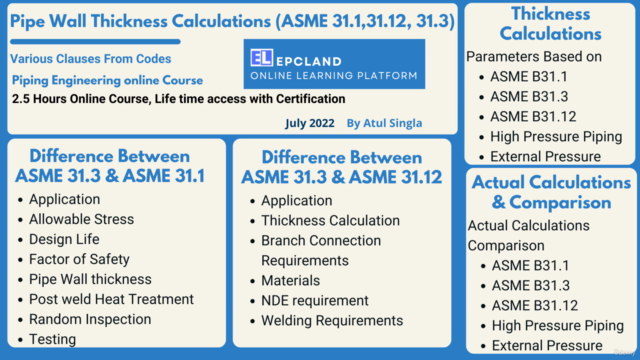

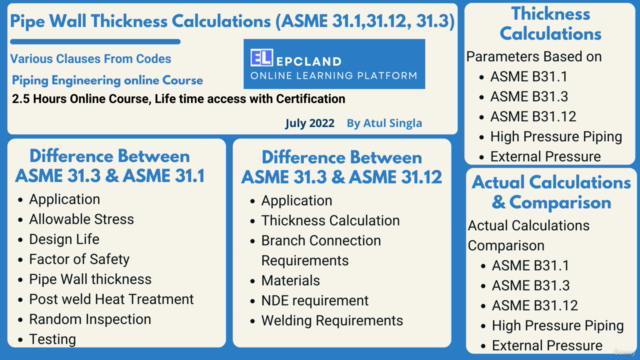

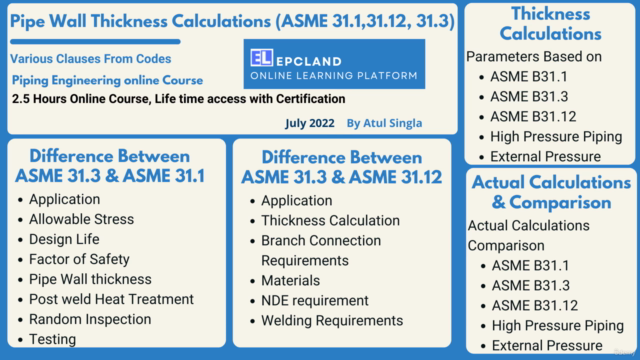

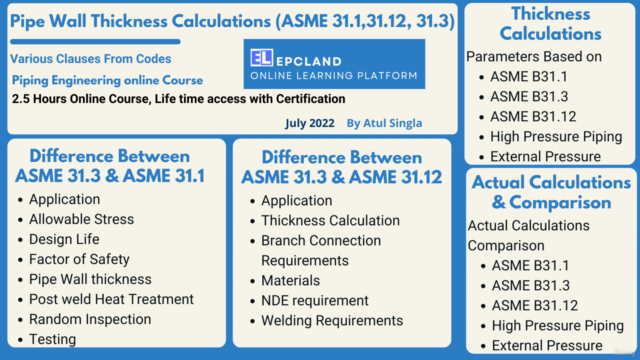

Pipe Wall Thickness: Various Codes ASME B 31.1, 31.12, 31.3

Difference Between ASME 31.3 & ASME 31.1, Thickness calculations for High Pressure pipe, External Pressure

What you will learn

Pipe Wall Thickness based on ASME B 31.1

Pipe Wall Thickness based on ASME B 31.12

Pipe Wall Thickness based on ASME B 31.3

Pipe Wall Thickness : External Pressure

Pipe Wall Thickness : High Pressure

Why take this course?

Pipe thickness calculations are very important aspects of Piping Engineering. Process piping, Hydrogen Piping, Power plant has different codes which need to be followed while calculating the thicknesses. Also, the High pressure piping has different criteria to calculate the thickness. Moreover, External piping’s thickness calculations are different than the others.

In this course following shall be covered:

1. Difference Between ASME 31.3 & ASME 31.1

Application

Allowable Stress

Design Life

Factor of Safety

Pipe Wall thickness

Post weld Heat Treatment

Random Inspection

Testing

2. Difference Between ASME 31.3 & ASME 31.12

Application

Thickness Calculation

Branch Connection Requirements

Materials

NDE requirement

Welding Requirements

3. Thickness Calculations

Parameters Based on

ASME B31.1

ASME B31.3

ASME B31.12

High Pressure Piping

External Pressure

4. Actual Calculations & Comparison

ASME B31.1

ASME B31.3

ASME B31.12

High Pressure Piping

External Pressure

Also, check out the quiz section on Pipe wall thickness on EPCLand, where hindered of quizzes , articles and detailed courses have been published.

Frequently Asked Questions:

What is ID and OD of pipe?

The outside of the pipe is always larger than the inside. The difference between the inside diameter (ID) and the outside diameter (OD) is due to the thickness of the wall.

What is the thickness tolerance in pipe?

The most common tolerance on the wall thickness of straight pipe is 12.5%. This means that the wall thickness at any given location around the circumference of the pipe must not be less than 87.5% of the nominal wall thickness.

What is required thickness?

The minimum thickness without corrosion allowance for each element of a pressure vessel based on the appropriate design code calculations and code allowable stress that consider pressure, mechanical, and structural loadings.

What unit is thickness?

A "mil" is a unit of thickness equal to one thousandth of an inch (. 001 inch). To convert mil to inches, take mil and divide by 1000.

What is minimum required thickness?

The thickness without corrosion allowance for each component of a piping system based on the appropriate design code calculations and code allowable stress that consider pressure, mechanical and structural loadings.

Is pipe sized by ID or OD?

Tube is measured by outside diameter, pipe is measured by inside diameter.

How do you calculate percent thickness?

t = P * D / (2 * F *S * E)

1. t : Calculated Wall thickness (mm)

2. P : Design pressure for the pipeline (kPa)=78 bar-g=7800 KPa.

3. D : Outside diameter of pipe (mm)= 273.05 mm.

4. F : Design factor = 0.72.

5. S : Specified Minimum Yield Strength (MPa)=359870 KPa for the specified material.

6. E : Longitudinal joint factor = 1.0

What is STD in piping?

In pipes engineering, STD refers to standard thickness. Each pipes was produced to have one thickness that was later termed as STD. Schedule STD Steel Pipes is available in extra strong (XS), extra heavy (XH), double extra strong (XXS), and Double extra heavy (XXH).

What is ASME B36 10M?

B36.10M Welded and Seamless wrought steel pipe

This standard covers the standardization of dimensions of welded and seamless wrought steel pipe for high or low temperatures and pressures.

What is ASME B36 19m?

This Standard covers the standardization of dimensions of welded and seamless wrought stainless steel pipe for high or low temperatures and pressures. The word pipe is used, as distinguished from tube, to apply to tubular products of dimensions commonly used for pipeline and piping systems.

Why is it called Schedule 40?

Why is it called schedule 40 pipe? The pipe numbers are non-dimensional. In other words, SCH 40 doesn't mean the pipe is 40 millimeters or 40 inches in diameter. The parameters for each schedule are determi

Screenshots

Reviews

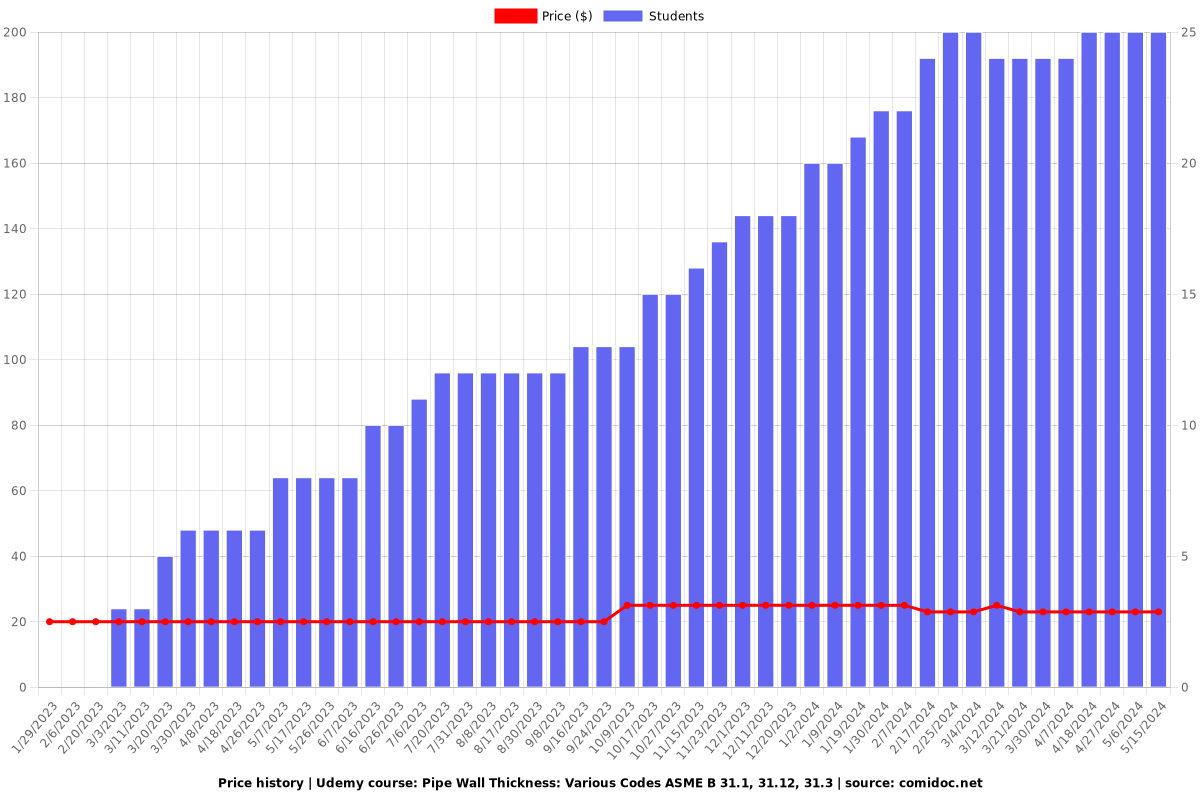

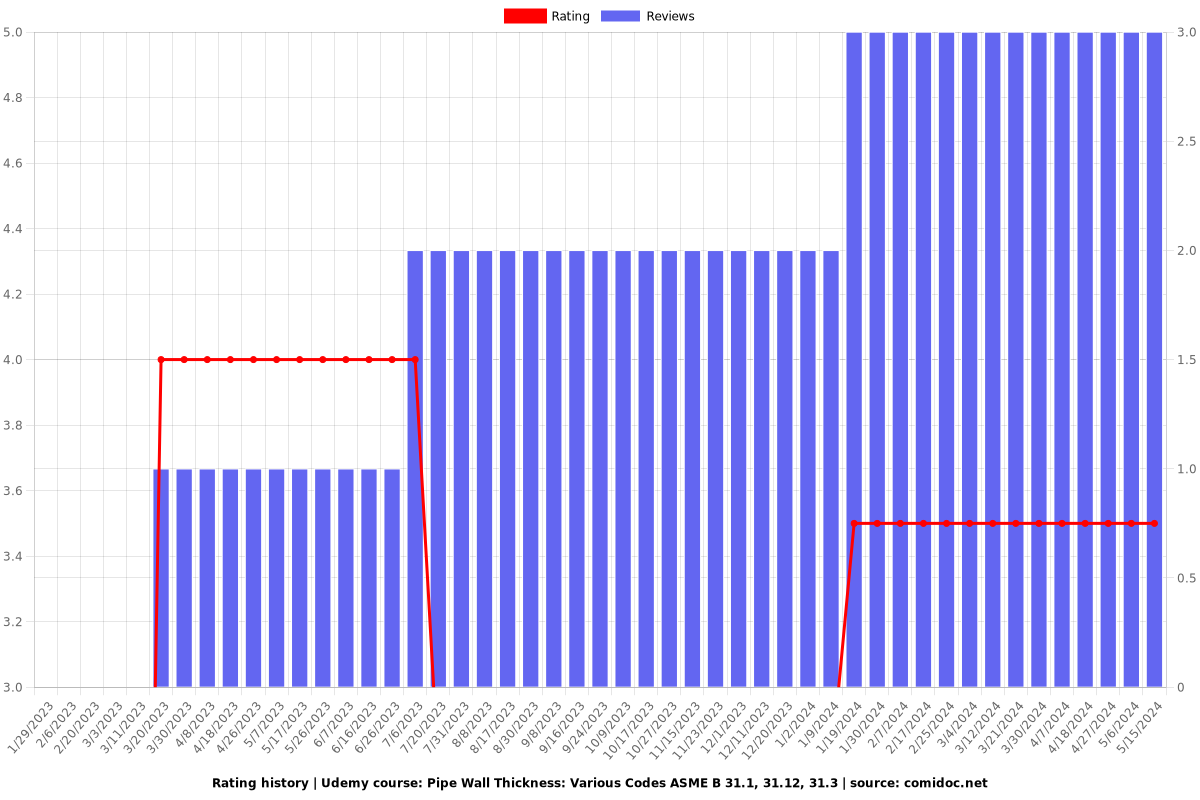

Charts

Price

Rating

Enrollment distribution