Aggregate Capacity Planning

Aggregate Capacity Planning is important to know the change in demand and plan for the capacity to meet those demands

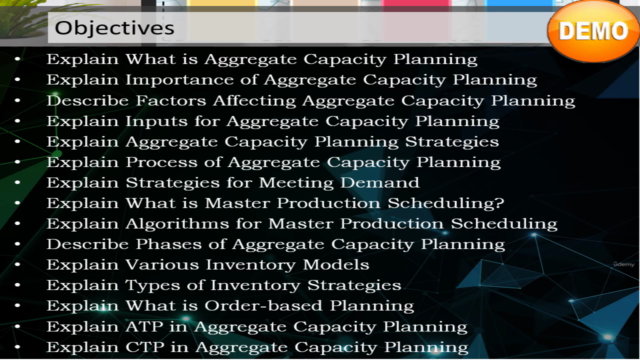

What you will learn

Explain What is Aggregate Capacity Planning

Explain Importance of Aggregate Capacity Planning

Describe Factors Affecting Aggregate Capacity Planning

Explain Inputs for Aggregate Capacity Planning

Explain Aggregate Capacity Planning Strategies

Explain Process of Aggregate Capacity Planning

Explain Strategies for Meeting Demand

Explain What is Master Production Scheduling?

Explain Algorithms for Master Production Scheduling

Describe Phases of Aggregate Capacity Planning

Explain Various Inventory Models

Explain Types of Inventory Strategies

Explain What is Order-based Planning

Explain ATP in Aggregate Capacity Planning

Explain CTP in Aggregate Capacity Planning

Why take this course?

An organization can finalize its business plans on the recommendation of demand forecast. Once business plans are ready, an organization can do reverse calculation from the final sales unit to raw materials required. Thus, annual and quarterly plans are broken down into labor, raw material, working capital, etc. requirements over a medium-range period of about 6 months to 18 months. This process of working out production requirements for a medium-range is called ‘Aggregate Planning’. Aggregate planning will ensure that organization can plan for workforce level, inventory level, and production rate in line with its strategic goals and objectives.

‘Aggregate Planning’ helps achieve balance between operation goal, financial goal and overall strategic objectives of the organization. It serves as a platform to manage capacity and demand planning. In a situation where demand is not matching the capacity, an organization can try to balance both by pricing, promotion, order management, and new demand creation. •‘Aggregate Planning’ is an operational activity critical to the organization as it looks to balance long-term strategic planning with short-term production success.

Production levels or capacity from normal working hours, overtime working hours, and subcontracted hours. This will give an estimate of the workforce numbers and supplier purchase levels. As the name suggests, ‘Level Strategy’ looks to maintain a steady production rate and workforce level. In this strategy, organization requires a robust forecast demand as to increase or decrease production in anticipation of lower or higher customer demand.

There are several techniques that can be used for Aggregate Planning in an organization.

It can be informal trial-and-error methods or proper structured processes or even advanced techniques using statistical tools to plan for aggregate capacity planning to match the changes in demand.

Screenshots

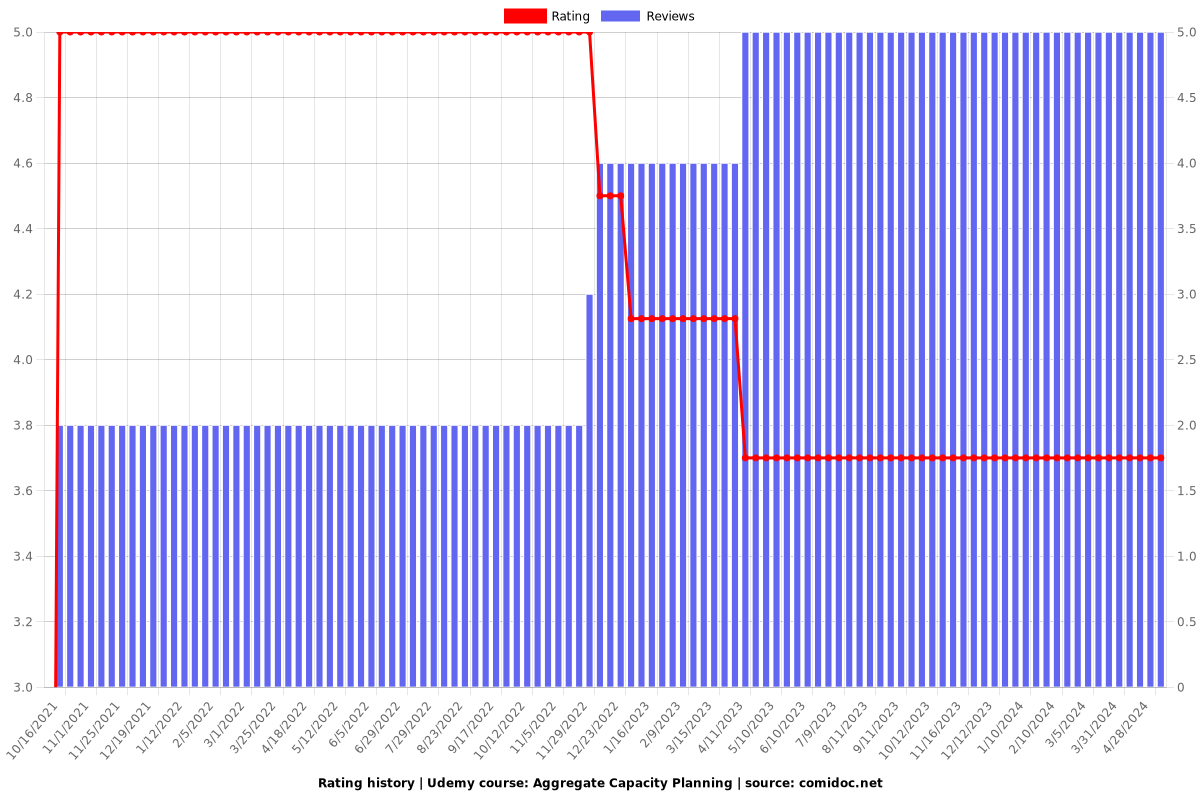

Reviews

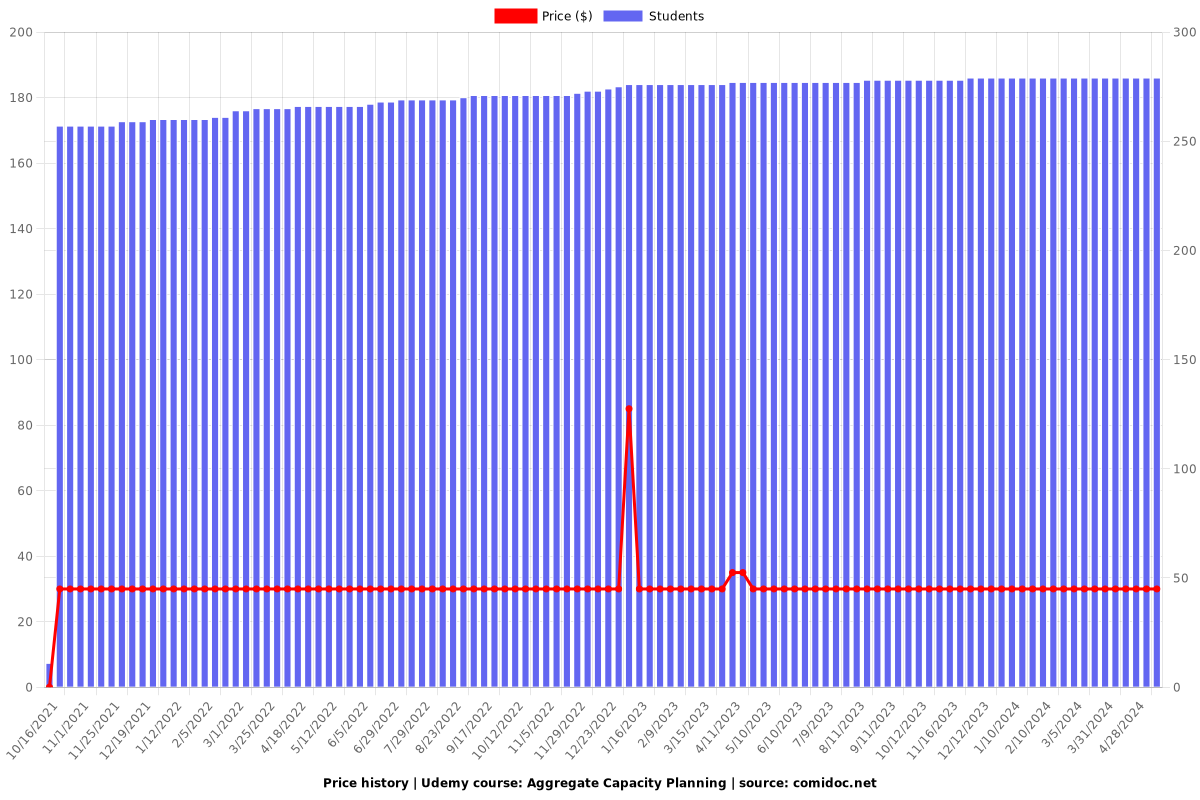

Charts

Price

Rating

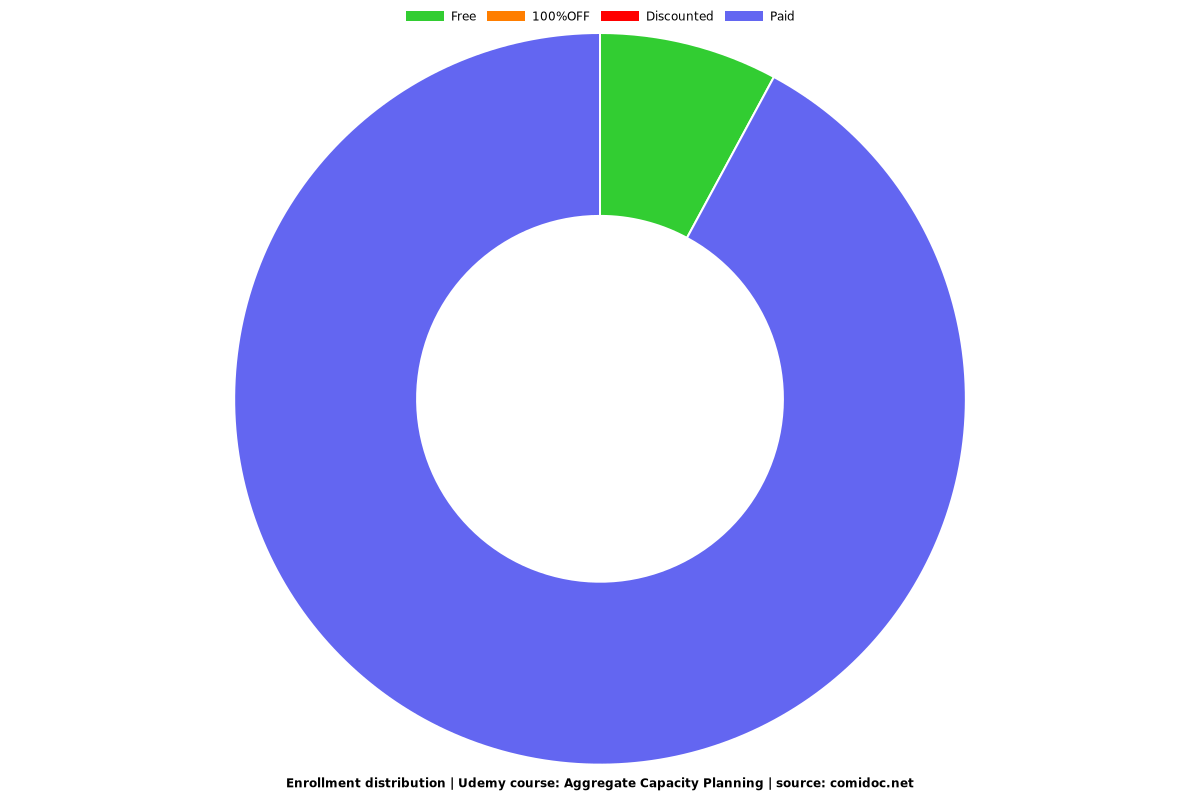

Enrollment distribution