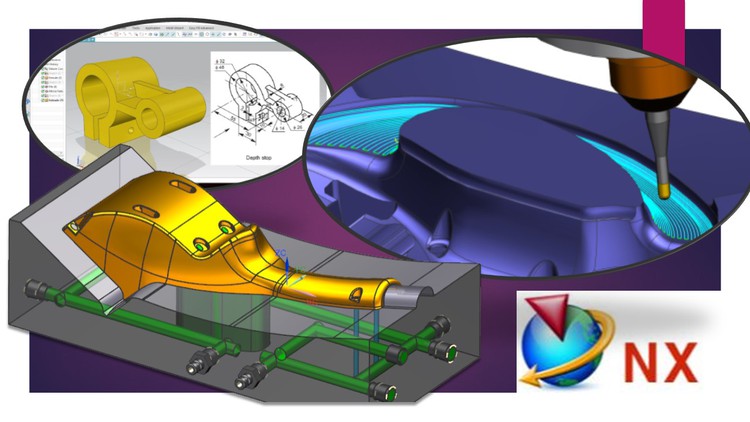

Siemens NX CAD/CAM&Post Builder/Mold (CAM 2027 Interface)

3D CAD & NX 2027 CAM Interface & Manufacturing (CAM) & Customize G Code (Post Builder) & Injection Mold (Mold Wizard)

4.67 (145 reviews)

1,547

students

13.5 hours

content

Oct 2023

last update

$64.99

regular price

What you will learn

You will learn how to make 3D Parts.

After this course, you will be able to create G code for Milling, Turning and Wire EDM operations (3 Axis & Multi Axis).

Additional NX CAM 2027 Interface sessions added to the course to be able to use the latest version.

You will be professional user in NX CAM.

You will learn the steps of NX Injection Mold (From start to the End).

You will be able to use NX CAD for Assembly & Drafting.

Related Topics

4847816

udemy ID

8/24/2022

course created date

8/27/2022

course indexed date

Bot

course submited by