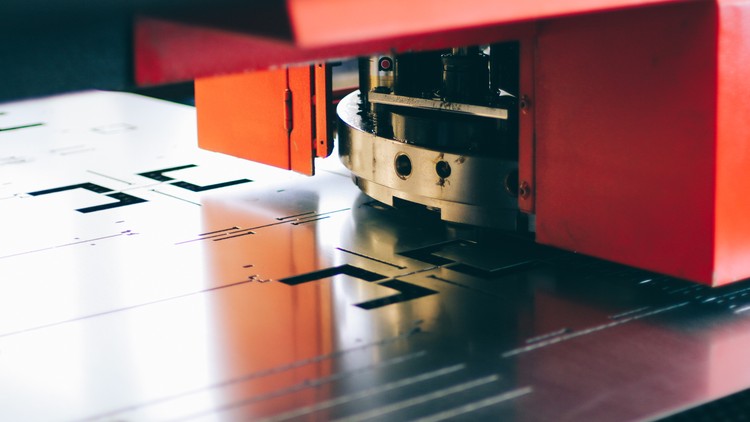

Basics of Sheet metal design for Mechanical design engineers

Learn Sheet metal design, processes and practical design considerations along with Design projects.

4.41 (1457 reviews)

6,636

students

7 hours

content

May 2024

last update

$79.99

regular price

What you will learn

How to design effectively with sheet metal

Guidelines to be followed when designing for sheet metal

Understand the principles at play behind the factors considered in design

How Material properties affect the Part quality and design considerations

Designing simple sheet metal brackets using Fusion 360

Screenshots

Related Topics

2014090

udemy ID

11/8/2018

course created date

5/5/2020

course indexed date

Bot

course submited by