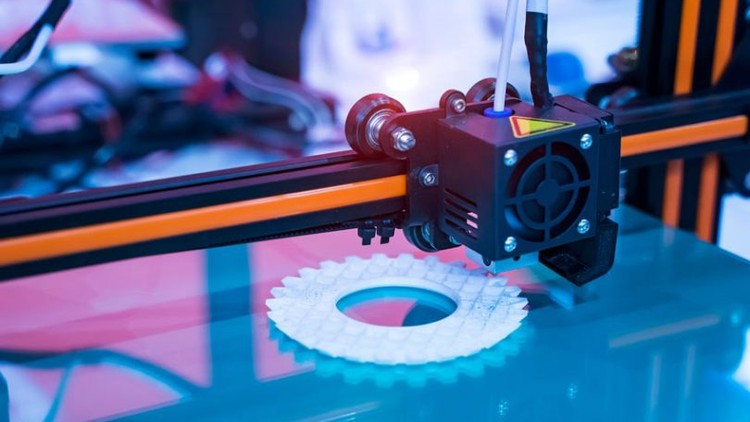

Fundamentals of Additive Manufacturing

An Introduction

3.66 (22 reviews)

79

students

1 hour

content

Dec 2019

last update

$29.99

regular price

What you will learn

Basic working principle of Additive Manufacturing

Materials used in Additive Manufacturing

Latest Innovations in Additive Manufacturing

Applications of Additive Manufacturing

Classification of Additive Manufacturing Process

Screenshots

Related Topics

2687038

udemy ID

12/3/2019

course created date

10/21/2020

course indexed date

Bot

course submited by