Advance Supply Chain Extensive Training 1 - ASCET 1

Deep dive into SCM Network Designing and Production Planning for Cost Optimizations To Increase Working Capital of firm

What you will learn

Learn the Basic and Fundamentals of Supply Chain Network and grow to Advance level

Learn different systems to manage flow of information for production

Learn how to meet demand without exceeding supply at any location or region while maintaining minimum cost

Master Planning Schedule (MPS)

Learn to assess company policies and programs and to meet targets to accomplish long‐term strategic objectives

You will be introduced to the Supply Chain Network Design Spectrum where you get to choose the best fit location for a facility among multiple places

Introduce yourself to Network Models

This course introduces you to Facility Location Models and Approaches

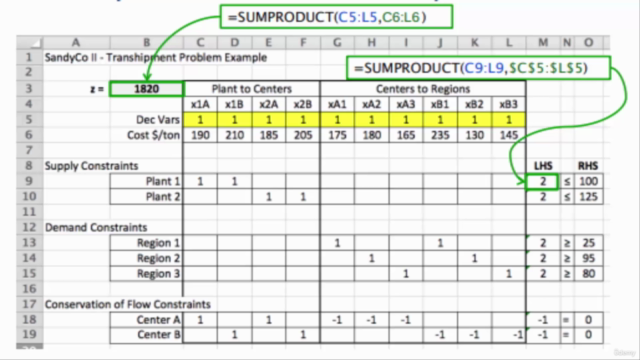

Learn how to do Transportation and Transshipment problems using spreadsheets ,

Learn how to do Programming Formulation for Supply Chain Network Models

You will be introduced to Continuous Single Facility Location Models

Your programmed models helps you decide among best option among Multiple Location Selections

COG and Weber Methods

Decide between Trade offs Cost and Level of Service (LOS)

Sensitivity Analysis Using Mixed Integer Linear Programming (MILP) Models

Logistics management with excel solver

Material Requirements Plan (MRP)

Distribution Requirements Plan (DRP)

Learn best manufacturing strategy that influences the production plans

Chase versus Level versus Hybrid production plans

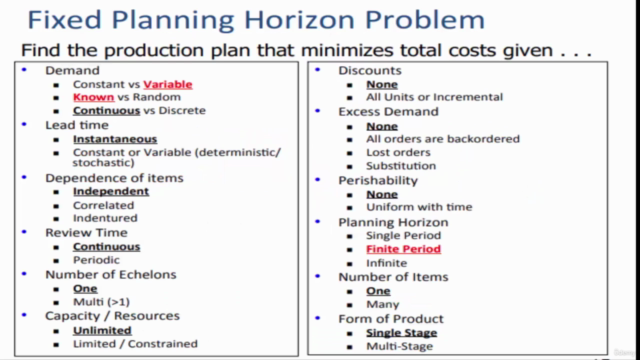

Learn Fixed Planning Horizon (FPH) or Lot Sizing

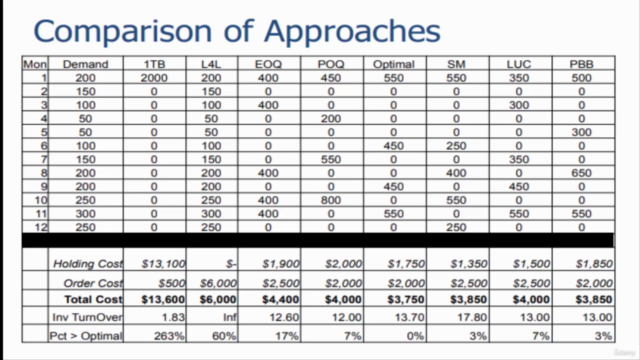

Heuristics versus Optimal Models

Introduction to Production Planning and Fixed Planning Horizons

Lot For Lot (LFL) , Fixed Order Quantity (FOQ) , Economic Order Quantity (EOQ) , Periodic Order Quantity (POQ)

Silver-Meal (Least Cost Period) , Wagner-Whitin (WW)

Production Planning and Mixed Integer Linear Programming (MILP)

Learn how to communicate forecasted demand for end items to manufacturing

Learn how to allows sales to determine Availability to Promise (ATP)

Time fencing reduces production "nervousness" ( Frozen vs Slush vs Water )

Determine quantity and timing of orders for components

Learn Uses of MPS & Bills of Material (BOM) as inputs

How to implement Coordination tool between firms

Learn Mirror image of MRP logic — roll up versus roll down

Learn Plans for flowing of finished end items through network to market

Demand And Supply Planning

Material Planning

Certification when you finish the course successfully

Why take this course?

Network Designing :

It is important to recognize that a company’s network determines its supply chain efficiency and customer satisfaction. Designing an optimal supply chain network means the network must be able to meet the long‐term strategic objectives of the company. Most business units or functional areas within a company are impacted by a network design project.

Production Planning :

Production planning is the planning of production and manufacturing modules in a company or industry. It utilizes the resource allocation of activities of employees, materials and production capacity, in order to serve different customers. Different types of production methods, such as single item manufacturing, batch production, mass production, continuous production etc. have their own type of production planning.

Production planning can be combined with production control into production planning and control, or it can be combined and or integrated into enterprise resource planning. Production planning is used in companies in several different industries, including agriculture, industry, amusement industry, etc. Production planning is a plan for the future production, in which the facilities needed are determined and arranged.

A production planning is made periodically for a specific time period, called the planning horizon. It can comprise the following activities: Determination of the required product mix and factory load to satisfy customers needs. Matching the required level of production to the existing resources. Scheduling and choosing the actual work to be started in the manufacturing facility" Setting up and delivering production orders to production facilities. In order to develop production plans, the production planner or production planning department needs to work closely together with the marketing department and sales department. They can provide sales forecasts, or a listing of customer orders." The "work is usually selected from a variety of product types which may require different resources and serve different customers. Therefore, the selection must optimize customer-independent performance measures such as cycle time and customer-dependent performance measures such as on-time delivery." A critical factor in production planning is "the accurate estimation of the productive capacity of available resources, yet this is one of the most difficult tasks to perform well." Production planning should always take "into account material availability, resource availability and knowledge of future demand."

This is a course you should do if you wish to develop skills to enter the domain and excel of supply chain management.

Content

Introduction To Network Models

Facility Location Models

Production Planning and Fixed Planning Horizon Models

Material And Distribution Requirements Planning

Screenshots

Reviews

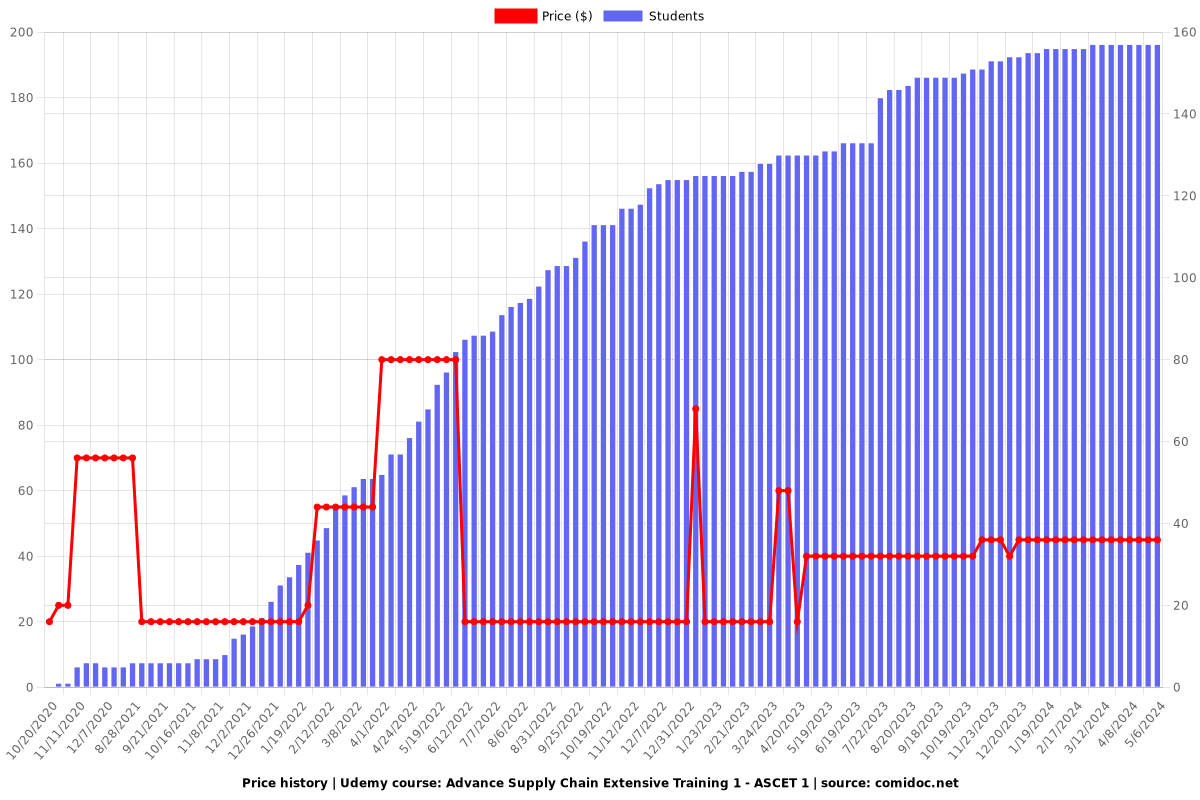

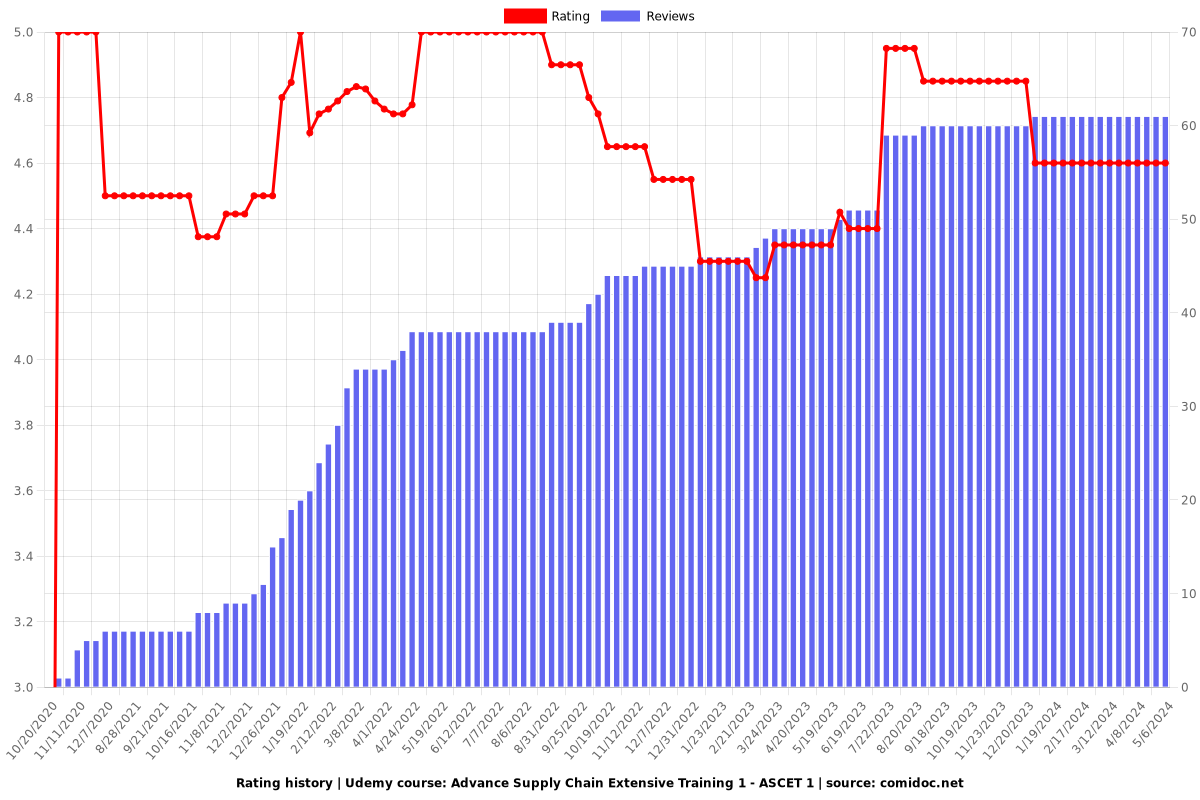

Charts

Price

Rating

Enrollment distribution